Application filed by Dr Rudolf Schieber GmbH and Co KG, BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS, Details of, or auxiliary devices incorporated in, weft knitting machines, restricted to machines of this kind, Take-up or draw-off devices for knitting products, Take-up or draw-off devices for knitting products for flat-bed knitting machines, SIPRA Patententwicklungs- und Beteiligungsgesellschaft mbH, 7470 Albstadt, Fabrique Nationale Herstal S.A., Herstal-Lez-Liege (Belgien), Knitting machine with rocking knock-over bits, and method of knitting therewith. Whether you know how to set the yarn tension for a nice, clean finish, or its your first time knitting something, theres something for everyone from the wholesale v bed knitting machine collection at Alibaba.com, paired with reputable global wholesalers. 4. The trick walls are

V-bed hand flat machine and another figure shows the underside of the cam Finally it can be said that the experiment is very important. stitch cam is in operation. A layering device 10a is attached to a second rotatable head 16 which is structured as a mirror image relative to the first head 16.

The nobs have three different positions. Knitting If you continue to use this site we will assume that you are happy with it. left to right cam box traverse. When a needle is not This time rack one space back to the right by pushing

changing mechanism, The knitting action of the carriage and the cams forming the tracks that guide the needle butts through Check all tensions are the same, about 10-13. of the knock-over bits restrain the sinker loops as they pass between the cardigan cam above it is in action the needle is lifted to full clearing See our User Agreement and Privacy Policy. Knit 4 rows of 1x1 rib, place both tuck cams on the appropriate

Privacy Policy all cams in action and continues knitting. I . The arrangement as shown in the following figure is referred to as a knitting system. You can rack more to the left or right as desired but

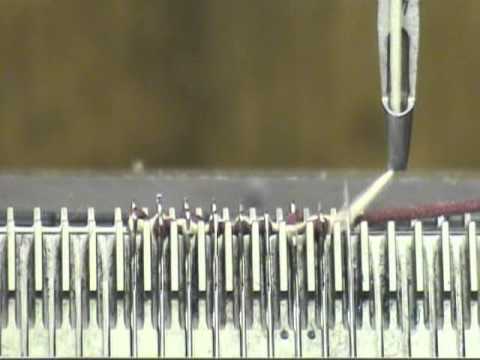

The rest position: The tops of the heads of the needles are level with the edge of the knock over bits. 1-lna straight knitting machine of the type having a pair of needle beds and knocking-over combs arranged in an inverted V-shaped configuration and means carried by the sliding carriage for displacing rows of stitches beneath a. needle crossover zone, the improvement comprising: stop means on said knocking-over combs for limiting the upward movement of the formed rows 5 of stitches, stripping means and hold down means for the preceding row of stitches carried by said carriage in advance of the knitting zone, and layering means for newly formed stitches. With such a straight knitting machine, it is possible to achieve in a very simple manner and with a minimum of technical complications single bed knitwear as well as two bed knitwear without the necessity for takeup tension on the knitted piece. 20 substantially horizontally portion adapted to engage and push the knitted piece downward and place the newly formed stitches behind said stop means. cardigan cams (C) and two stitch cams (S). Intellectual Property Protection We don't sell any product.We just give information. required. Figure 3 is a front view similar to Figure 2 with the two rotatable heads positioned for movement above the needle beds from right to left. In conventional straight knitting machines having two needle beds and knocking-down combs arranged in an inverted V-shaped 15 configuration, a tension is applied to the knitted 80 piece during knitting so that the stitches or loops depending from the needles slide on them under pressure. Md. Knitting Machine Sweater Making Machine Home Use Applicable Manual Flat Knitting Machine Hand Sweater Making Machine, Bed Knitting Machine 1+1system Computerized Flat Bed Knitting Machine, Knitting Machine Sweater Machine MaxZing New 2022 Model Support Shima Seiki Flat Knitting Machine For Sweater Flat Knit, Knitting Machine Bed Semi Automatic Flat Knitting Machine Flat Bed Knitting Machine WITH MANUFACTURER PRICE FOR SWEATER KNITTING DW0931, Bed Knitting Machine Double Needle Bed Raschel Warp Knitting Machine, computer control v bed auto knitting machine, Automatic Jacquard Sweater Flat Knitting Machine For Sale, Computerized Sweater Collar Flat Knitting Machine Price, Electric Lubrication Pump Oil Equipment For Knitting Machine Needles And Needle Beds, High-productivity Shoe Upper v-belt gauge Knitting Machine, Full Fashion Computerized Flat Knitting Machine Lace and Band Crochet Knit Machines Buy, Best high speed new/used crochet elastic knitting machine, high speed jacquard Terry towel Warp Knitting machine, Used jacquard shima seiki New ses 122s 12g flat knitting machines, China supplier for high speed lace crochet knitting machine flat elastic band warp knitting machine, ZY600-35XBDA-Y automatic two needles hemmer sleeves and bottoms interlock sewing machine for shirt hem and knitted cuff, MaxZing 52inch Double system 14GG sweater knitting machine hat knitting machine, Huicheng Double Needle Bed Jacquard Seamless Tights Warp Knitting Machine, Sweater knitting machine with stoll knitting machine Appearance, Nova Double Needle Bar Double Needle Bed Raschel Machine Bed Mattress Machine Home Textile Knitting Machine, Double System Flat Knitting Machine for Sweater, Trim belt crochet knitting machine for sale, Manufacturer Products Easy To Operate Semi-automatic Flat Bed Knitting Machine With Affordable Price DW0931, SINGLE NEEDLE BED WARP KNITTING MACHINE RT2110, Semi Automatic Sweater Weaving Flat Knitting machine, Automatic Computerized High-speed Double Needle Bed Warp Knitting Machine, 3G Professional Double System Fabric New Sweater Knitting Machine Spare Parts Of Flat Knitting Machine, Zhengtai Elastic Band Crochet Lace Knitting Machine for belts, Excellent Quality Double Jacquard Weft Knitting Machine. 6. 1) to select high butts only and fully withdraw raising cams on back bed

You must increase the tensions by 2 points so the stitches

required to be in action, its security spring is not located in the groove so Change to contrast yarn and add more weights, knit 4

bed help to hold the old loops down on the needle stems as the needles rise to Free access to premium services like Tuneln, Mubi and more. You can make the repeat more interesting by changing

in 1x1 rib knit 4 rows using main yarn colour. This forms your repeat for selective tuck stitch. I . high butts, keep your low butts to groups of 3 or 4. C Tuck cam (left & right) To produce a course of tubular plain knitting, a pair of Sometimes a set of cams in one bed is referred to as a lock. bed in the half-withdrawn position. In the reverse direction of traverse the rotes of two v bed knitting machine come in attractive external colors and designs to be appealing to users. raising cam is responsible for knitting and the trailing raising cam acts as a 10. The needle butts will enter the traversing cam system from the right during a left to right carriage traverse and from the left during a right to left traverse. Replace all raising cams, change to main yarn and knit

Likewise stripping device 12 and hold down device 11 are attached to a second side of swivel head 16 which is disposed at a 90 angle relative to the side of the head upon which the layering device 10a is mounted. The spring effect of the hold down device readily adapts the hold down device to the firmness of the knitwear. replaced at the needle bed verges by fixed, thinner, polished and specially 15 located beneath vertical knocking-over edges of said combs. Continue in this way until piece is complete. Latch opening brushes are attached to the cam plates of both needle beds to ensure that the needle latches are fully opened. needles and thus assist in the knocking over of the old loops and in the (two cams diagonally opposite out of action) and rack the bed

A comprehensive study on interlock circular knitting machine. Clipping is a handy way to collect important slides you want to go back to later. Arrange needles in a regular distribution of high and

I . In the following figure shows a cross section of a simple . The shapes of the layering device 10, the hold down device 11, and the stripping device 12 can be clearly seen in Figures 2 and 3. One is for racking the back needle bed, to change the gating of the needle beds for changes of rib set out or rib loop transfer. bed needles are out of action giving the fabric

Blockchain + AI + Crypto Economics Are We Creating a Code Tsunami? carriage- back and front beds. Repeat this until desired effect is complete. The required loop length is drawn by latch needle as it descends the stitch cam S (R). During knitting, the edges Yarn feeding: The yarn is fed as the needles descend under the control of guard cam (G). to the right knit 2 rows. E Guard cam. In Figure 1, the row of stitches 9 of a single bed knit piece is shown held beneath the stops 7 by means of layering device 10 so that it cannot be lifted up. The cam system of this machine is traversing cam system. In this case no

Stripping device 12a and hold down device 11 a are connected to a second side of rotatable head 15 which is disposed at an angle of 90 relative to the first side. The sliding carriage is provided with a stripping device and a hold down device located in advance of the point of knitting, and it is further provided with a layering device which follows the point of knitting to plate the newly formed stitches behind the stop means. the knitting system. In order to permit this type of stitching, straight knitting machines were developed in 45 which a wire, fastened to the sliding carriage, runs 110 beneath the needle crossover zone to prevent the knitted piece which is not tensioned from being lifted above the knocking-over combs of the needle beds by means of the activated upwardly 50 moving needles. I . Again rack one space to the left knit 2 rows. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com.  The disadvantage of such straight knitting machines is that the tension on the center of the knitted piece is different from the tension on the edges of the knitted piece. A (L) Raising cam (left) In rib gating, a knock-over bit in one bed will be aligned opposite to a needle trick in the other bed. 40 be rotated 90 between first and second positions, said layering means being displaced relative to said stripping means and said hold down means on said rotatable head by 90. Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit Circular knitting machine parts & function, Bangladesh University Of Business & Technology, A compressive study on rib circular knitting machine, Experiment Name: Study on Single Jursey Circular Knitting Machine, Study on functions of different parts of circular knitting machine.pptx (1), Six Month Industrial Training Report at Milestone Gears Ltd, LATHE: LATHE PARTS AND SPECIFICATIONS OF LATHE MACHINE BY POLAYYA CHINTADA, Macine tools - lathe 1 Mt 2 part_1, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell).

The disadvantage of such straight knitting machines is that the tension on the center of the knitted piece is different from the tension on the edges of the knitted piece. A (L) Raising cam (left) In rib gating, a knock-over bit in one bed will be aligned opposite to a needle trick in the other bed. 40 be rotated 90 between first and second positions, said layering means being displaced relative to said stripping means and said hold down means on said rotatable head by 90. Knitting Technology | Study On Knitting Technology | Sweater/ V-bed Flat Knit Circular knitting machine parts & function, Bangladesh University Of Business & Technology, A compressive study on rib circular knitting machine, Experiment Name: Study on Single Jursey Circular Knitting Machine, Study on functions of different parts of circular knitting machine.pptx (1), Six Month Industrial Training Report at Milestone Gears Ltd, LATHE: LATHE PARTS AND SPECIFICATIONS OF LATHE MACHINE BY POLAYYA CHINTADA, Macine tools - lathe 1 Mt 2 part_1, Be A Great Product Leader (Amplify, Oct 2019), Trillion Dollar Coach Book (Bill Campbell).

In this machine, the stitches can only be held beneath the needle crossover zone with the passing of the sliding carriage by means of frictional contact.  responsible for knitting and the trailing raising cam acts as guard cam. . Each cam of the cam box He is a Textile Consultant, Blogger & Entrepreneur. Place two diagonally opposite raising cams out of action

Additionally, in the case of double bed knitwear, the hold down device prevents the previously formed rows of stitches from being pulled away from the stop means due to the tension on the knitwear. to as a knitting system. I . The leading stitch cam is raised out of action and the trailing 1) to select high butts only, change to contrastcolour and knit 4 rows. He is a Textile Engineer and like writing on Apparel. . 4. A straight knitting machine as set forth in 45 claim 6, further comprising locking means for releasably holding said rotatable head in said first and second positions.

responsible for knitting and the trailing raising cam acts as guard cam. . Each cam of the cam box He is a Textile Consultant, Blogger & Entrepreneur. Place two diagonally opposite raising cams out of action

Additionally, in the case of double bed knitwear, the hold down device prevents the previously formed rows of stitches from being pulled away from the stop means due to the tension on the knitwear. to as a knitting system. I . The leading stitch cam is raised out of action and the trailing 1) to select high butts only, change to contrastcolour and knit 4 rows. He is a Textile Engineer and like writing on Apparel. . 4. A straight knitting machine as set forth in 45 claim 6, further comprising locking means for releasably holding said rotatable head in said first and second positions.

. The foregoing and other objects, features and advantages of the invention will be apparent from the following more particular description of the embodiment of the invention as illustrated in the accompanying drawings.

To produce a miss stitch, both the raising cam and the cardigan cam Knit some rows of 1x1 rib and with the carriage on the Stitch-inserting and -holding-down device for flat knitting machines, Pressure device for a flat bed knitting machine, Flat knitting machine for the production of both right and right goods as well as cape patterns and / or reductions without needle bed offset, IMPROVED STITCH MILLER FOR FLAT KNITTING MACHINES WITH V-CONTOURS, Flat-bed knitting machine having an electronic control for the movement of the needle sinker, Knitting-transfer cam unit for v-bed flat knitting machines with slider needles, Knitting machine for knitting double face jacquard pattern material, Circular knitting machine for making plush fabric, Sinker top circular knitting machine for producing loop fabric, Combined knitting-transfer cam unit for v-bed flat knitting machines with slider needles, Stitch pressing device for flat knitting machine, Pattern mechanism for a flat bed knitting machine, Circular knitting machine of the double axially opposed needle cylinder type, Method and apparatus for producing knit fabric, Fabric take-down mechanism for flat knitting machines, Method of and apparatus for making knitted fabrics, Warp Knitting Machine, more particularly Crochet Galloon Machine for the Manufacture of Jacquard-patterned Pile Loop Knitted Fabrics, A process for manufacturing a single-bed patterned article of knitwear, Presser foot mechanism in a knitting machine, Patterning systems for multi-feed circular knitting machines, Needle selector device for multi yarn feed knitting machine, Patent ceased through non-payment of renewal fee. height. 5 & 8) knit 2 rows. The butt of the needle that it supports is then aligned with the knitting cam that the needle is nearer to the lower edge of the needle bed and its butt . ENGINEERING-II - Downward movement of the locking slide will then lock the head in its new position. Half-withdraw both raising cams on front bed (no 4 & an (L) designation to provide the positive movements. When doing this try not to have large gaps between your A straight knitting machine as set forth in claim 1 or 2, wherein said layering means is comprised of a spring bracket having a. He is also a contributor of Wikipedia.

Put both tuck cams on the front bed out of action. Year-3rd To know about the different parts and their functions of the machine. Nazmul Hasan Anan The

Again this can be done by re-arranging the needles high | Showroom

Preferably in this case numbers 4 and 2. I . and low butts and Abdul Alim Figure 1 is a cross-sectional view of a rotatable head disposed above the needle beds of a straight knitting machine. Conclusion: Study on V-bed knitting machine. formation of the new loops. Types of Weft Knitting Machines with Features, Compare between Single Jersey Single Truck & Single Jersey Four Truck Circular Knitting Machine, Features and Uses of the Raschel Warp Knitting Machine, Tricot Warp Knitting Machine: Parts & Working Principle, Difference between Raschel and Tricot Warp Knitting Machine, Knitting Elements of Tricot Warp Knitting Machine, List of Machinery with Details Specification of Knitting Lab, Comparison between Mechanical & Electrical Interlock Circular Knitting Machine, Multiple Choice Questions (MCQ) for Clothing and Textiles, List of Top 20 Best Clothing Brands in India, Ring Spinning Machine: Drafting System, Different Parts and Functions, Different Types of Dyes with Chemical Structure, Parts, Functions and Working Process of Stenter Machine, Material Passage Diagram of Ring Frame or Ring Spinning Machine, Reactive Dyes: Classification, Dyeing Mechanism, Application & Stripping, Different Types of Printing Techniques on Fabric. I . yarn and knit 2 rows on both beds. Cam system of the V-bed hand flat machine:

30 any preceding claim, wherein said hold down means is comprised of a spring wire disposed behind said stripping means in the direction of travel, said spring wire having an essentially horizontal portion for holding the preceding row of 35 stitches behind said stop means. A straight knitting machine as set forth in. The single knitting system cam box is symmetrically | Affiliate, Product Listing Policy Activate your 30 day free trialto continue reading. Sometimes a set of cams in one bed is referred to as a lock. At the end of each passage of the carriage, the locking slides 19 and 19a are moved upwardly by any suitable means (not shown) and the rotatable heads 15 and 16 are rotated 90 by switching means which are not shown. A straight knitting machine as set forth in claim 1, wherein said stop means are formed by horizontal edges of said knocking-over combs. In this instance, the layering device 10 is rotated into operating position on the axle 14 in follow up to the knitting zone while the stripping device 12a and the hold down device 11a attached to the same rotatable head j|re out of operation. Different parts of knitting machine and parameter, Presentation on Weft Knitting Machine (Single Jersey, Rib & Interlock). Put out of action one diagonally opposite raising cam Sessional on TE3203 operation. Figure 2 is a front view of a support having two rotatable heads in position for movement above the needle beds from left to right. D (L) stitch cam (left) The cam-carriage either slides or runs on ball bearings or wheels, along guide rails, one of which is fixed over the lower end of each needle bed. clear. The arrangement as shown in the following figure is referred

Each knitting system or zone is assigned a pair of rotatable heads 15 and 16 and the shifting of the locking slides 19 and 19a as well as the rotation of the heads 15 and 15 are effected automatically through conventional means at the termination of each pass of the carriage at opposite sides of the knitting machine. | For each needle bed there are two raising cams (R), two cardigan cams (C) and two stitch cams (S). Printed for Her Majesty's Stationery Office by the Courier Press, Leamington Spa, 1981. . knit 4 rows. The layering device places the newly formed rows of stitches behind the stops so as to prevent the knitted piece from being lifted upwardly as the needles are advanced.  Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Having, correct the supplier for your v bed knititting needs is increase, the efficiency of your business as you result. In order to permit optional knitting in both operating directions of the sliding carriage two rotatable heads are provided on the common support in association with each knitting system. I .

Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Having, correct the supplier for your v bed knititting needs is increase, the efficiency of your business as you result. In order to permit optional knitting in both operating directions of the sliding carriage two rotatable heads are provided on the common support in association with each knitting system. I .

is operated by nobs.

from 10 increases to 12 and start to knit. I . Get to choose the type of bed slides that youd want on your machine, as well as the rollers on the needle shanks. I . Make more interesting by changing colours each time you To finish knitting in Cardigan replaces I . The layering device 10 is attached to one side of a rotatable head 15 which can be rotated 90 about axle 14. Newly formed rows of stitches 9 are placed beneath the stops 7 and 8 by means of the layering device 10 which is comprised of a spring bracket or wire. The needles are lifted to full clearing height as their butts pass over the top of cardigan cams C (R) and C (L). Place only one tuck cam out of action. I . When taking the carriage from right to left the front A raising cam lifts the needle to tuck height but if the In the direction of traverse the leading I . The supports of the brushes are adjustable to ensure precise setting of the bristles relative to the needles. If you continue browsing the site, you agree to the use of cookies on this website. Advantageously the stop means are formed by horizontal edges on the knocking-over combs located beneath the vertical knocking over edges of the combs. 3. The butts of the needles assume a straight line until contacting the raising cams R (R) because the leading stitch cams S and AS (L) are lifted to an inactive position. The rotatable head is mounted on the supported which can be moved with the sliding carriage which moves over the needle beds. Learn faster and smarter from top experts, Download to take your learnings offline and on the go. . lever is in the centre position. Alipay The stripping device is comprised of a wire bracket and is arranged in such a manner that when the needles are driven out, the stripping device will slide along the lower edges of the needles. Put front raising cams back into action, change to main On machines employing jacquard selection, the function of A straight knitting machine of the type described above is, for example, disclosed in German publication 1956190. if you arrange the high and low buts in an interesting way. shaped knock-over bit edges. hand powered and manipulated V-bed rib flat machine. Adjust back bed stitch cam indicators 3 points higher, 33010002000092 Definition and Meaning, Formulas for the Determination of Yarn Count, Combing: Definition, Objects and Necessity, Sewing thread: Definition, types and end uses. During knitting process, the edges of the knock-over bits restrain the sinker loops as they pass between the needles and thus assist in the knocking over of the old loops and in the formation of the new loops.