It costs a bolt manufacturer $1,000 to produce 20,000 bolts. The structuring of MOQs can sometimes be complicated, as it can require split payments or recurring payments. Therefore, the economics of the transaction also drive the MOQ. Keep your product range at a reasonable size. If manufacturers cannot source raw materials, they will likely impose high minimum orders quantities (MOQs) as they will face inflated prices.

Basically, the Minimum Order Quantity (MOQ) is the fewest units agreed by the supplier, purchased simultaneously. PRO TIP: To see the sell-through rate of the products you carry, view the Sell-through rate by product report in Shopify admin. ERP (enterprise resource planning) and MRP (material requirements planning) platforms have automation at their core. The directive that most inventory planners abide by is to source inventory at the lowest possible price, and this is not always the smartest thing to do!

When it comes to MOQs, suppliers consider how many items they need to sell before they can break even and eventually make a profit.

Of course, you must calculate what your breakeven point is. Supplier MOQs, high and low, will have a major impact on your inventory. Introducing order confirmations on Thirdwatch! To advertise this incentive, you could add a banner to your website that says, Spend $50 and enjoy free shipping. Or you could convert first-time buyers by offering to ship their first order for free. As a retailer, you may have occasion to set up your own MOQ for certain products. Take the First STEP by Launching your Business Online! Instead, spend your working capital on inventory that frequently turns than falling into the trap of MOQs. It is essential to eliminate the slow-moving SKUs in the system to better deal with the Minimum Order Quantity. Holding costs also play an important role in determining the MOQ. For products that arent produced that often the MOQ will generally be higher. View easy to understand reports to spot trends faster, capitalize on opportunities, and jumpstart your brands growth. If you purchase a MOQ at a 20% margin and this inventory lasts you for one year, you have made a 20% margin over the year. Building professional relationships with your transaction counterparts will always work for you in the long run. An MOQ needs to be at a substantial discount if it is worth considering. Suppliers with MOQs are usually more transparent, as they communicate discounts applied based on order volume.

No matter the variations, suppliers will not want to store products for too long, as their finances will benefit from a quicker turnaround.

The plus side is that your administrative costs will be lower, as your orders will need to be placed less frequently. See inventory holding, KPIs and recommended actions. If youre using Shopify POS, install the Stocky app to get purchase order suggestions based on historical sales data or a products seasonality.

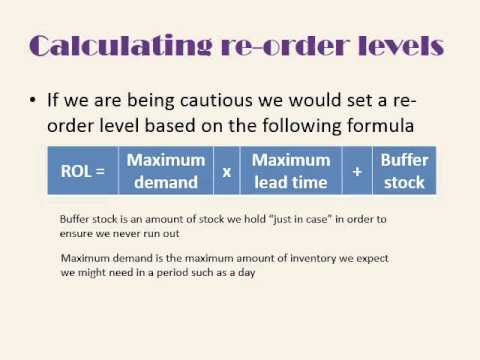

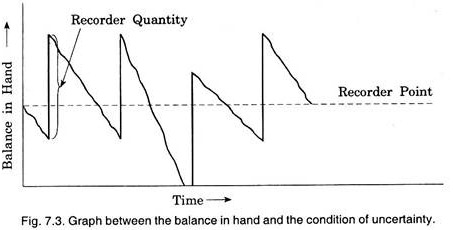

If you work with suppliers that have high MOQs, youll need to order a sizable amount of inventory, which might involve longer lead times. Typically, low MOQ products will have higher margins. Press Esc to cancel. It is a hassle-free system that you must use for your payment concerns. And if youre selling your products to retailers at wholesale, you can set an MOQ per style or collection, but also create tiers. Your supplier will have different economic constraints associated with your orders, depending on the products they sell. One should always be open to finding better deals online. It is equally important to get paid for your MOQ. In a perfect world, you would set up reorders on a schedule, and in quantities, exactly designed to meet customer needs. Liked this article? Lastly, the MOQ is also influenced by each suppliers business strategy. Of course, an MOQ is not always a bad thing. Of course, the MOQ may differ from supplier to supplier for the same item, so inventory buyers should review more than one supplier to establish the best MOQs to optimize their inventory planning. As we learned earlier, there are a few benefits of having MOQs. Redesigned app gives challenger organizations predictive inventory planning tools in a modernized, simplified and focused user interface. To address the problem of flagging orders and sending confirmation messages to your customers, we are over the moon to launch and present our latest addition to the Thirdwatch suite-, Market Demand and Its Value for an Aspiring Entrepreneur. Insights from the front lines of innovation. Obviously, suppliers have the upper hand, as MOQs ensure them financial gain and that theyll cover their costs. , business owners need not worry about RTO and CoD losses because the software tackles the hurdles with Artificial Intelligence and reduces order cancellations on your e-commerce store. Her specialties include content marketing and writing for SaaS and D2C ecommerce companies. It is essential to eliminate the slow-moving SKUs in the system to better deal with the Minimum Order Quantity. This means youll have to spend a minimum of $200 on pens per order. You also run the risk of holding onto the stock for too long, making it obsolete. This is the result of an economy of scale, whereby the supplier reduces its costs by increasing its production volume. It is essential to know the break-even point of a transaction because that provides the baseline for MOQ. Both the suppliers and the purchasers need to forecast the total number of units they wish to transact to come up with a minimum order quantity. And because the software provides near real-time data, you can quickly change your buying habits to meet current needs. They will set up an MOQ that takes minimum spend, minimum quantities, and minimum measurements of fabrics into account. MOQ (minimum order quantity): striking a balance, Warehouse Management System | Easy Mecalux WMS, Marketplaces & Ecommerce Platforms Integration, Copyright 2022 Mecalux, S.A. All Rights Reserved. Razorpay Route is one of the trusted ways to pay your clients or suppliers. See what smart inventory can do for your business. 5 Brands Designing for the Metaverse, Why People Buy: 5 Aspirational Marketing Tactics for Retail Brands. Here, well explore what an MOQ is, the impact of MOQs on your inventory, the benefits of MOQs, how suppliers calculate MOQs, and tips for optimizing MOQs. So, if a supplier sets a high MOQ, orders will be larger, and inventory fluctuations will be more marked. Suppliers set MOQs to avoid wasting time and resources on orders that deliver little or no profit. The impact of MOQs when managing your inventory, Tips to help navigate the complexities of MOQs, Netstock recognized as leader in G2 Summer 2022 Grid Reports, Five tips to manage supplier risk in your supply chain, Carrying excess stock? What is the impact of minimum order quantity on inventory? Dont be tempted to take shortcuts and ask for cheaper materials in the manufacturing process. The wholesale business is competitive, and one should always look for easier alternatives. PRO TIP: Always try to negotiate supplier pricing before you start the relationship (even if its $1 or a few cents less than the listed price). Imagine that this bolt manufacturer receives three orders a day, each with an average of 7,500 units. Consider calculating your MOQ to your customers as a safeguard. MOQs are an efficient way to save costs and deliver products. From the buyers point of view, MOQs clearly constitute a constraint. Having this in place weeds out customers who want to buy lower quantities, which leads to unprofitable orders. Stock Keeping Units (SKUs), if not managed properly, can severely affect the handling costs. Your friend may cut you a better deal. Even maintaining an inventory requires the costs of their own. This results in improved product quality, which also benefits the customer. The structuring of MOQs can sometimes be complicated, as it can require split payments or recurring payments. , if not managed properly, can severely affect the handling costs.

If you work with suppliers that have high MOQs, youll need to order a sizable amount of inventory, which might involve longer lead times. Typically, low MOQ products will have higher margins. Press Esc to cancel. It is a hassle-free system that you must use for your payment concerns. And if youre selling your products to retailers at wholesale, you can set an MOQ per style or collection, but also create tiers. Your supplier will have different economic constraints associated with your orders, depending on the products they sell. One should always be open to finding better deals online. It is equally important to get paid for your MOQ. In a perfect world, you would set up reorders on a schedule, and in quantities, exactly designed to meet customer needs. Liked this article? Lastly, the MOQ is also influenced by each suppliers business strategy. Of course, an MOQ is not always a bad thing. Of course, the MOQ may differ from supplier to supplier for the same item, so inventory buyers should review more than one supplier to establish the best MOQs to optimize their inventory planning. As we learned earlier, there are a few benefits of having MOQs. Redesigned app gives challenger organizations predictive inventory planning tools in a modernized, simplified and focused user interface. To address the problem of flagging orders and sending confirmation messages to your customers, we are over the moon to launch and present our latest addition to the Thirdwatch suite-, Market Demand and Its Value for an Aspiring Entrepreneur. Insights from the front lines of innovation. Obviously, suppliers have the upper hand, as MOQs ensure them financial gain and that theyll cover their costs. , business owners need not worry about RTO and CoD losses because the software tackles the hurdles with Artificial Intelligence and reduces order cancellations on your e-commerce store. Her specialties include content marketing and writing for SaaS and D2C ecommerce companies. It is essential to eliminate the slow-moving SKUs in the system to better deal with the Minimum Order Quantity. This means youll have to spend a minimum of $200 on pens per order. You also run the risk of holding onto the stock for too long, making it obsolete. This is the result of an economy of scale, whereby the supplier reduces its costs by increasing its production volume. It is essential to know the break-even point of a transaction because that provides the baseline for MOQ. Both the suppliers and the purchasers need to forecast the total number of units they wish to transact to come up with a minimum order quantity. And because the software provides near real-time data, you can quickly change your buying habits to meet current needs. They will set up an MOQ that takes minimum spend, minimum quantities, and minimum measurements of fabrics into account. MOQ (minimum order quantity): striking a balance, Warehouse Management System | Easy Mecalux WMS, Marketplaces & Ecommerce Platforms Integration, Copyright 2022 Mecalux, S.A. All Rights Reserved. Razorpay Route is one of the trusted ways to pay your clients or suppliers. See what smart inventory can do for your business. 5 Brands Designing for the Metaverse, Why People Buy: 5 Aspirational Marketing Tactics for Retail Brands. Here, well explore what an MOQ is, the impact of MOQs on your inventory, the benefits of MOQs, how suppliers calculate MOQs, and tips for optimizing MOQs. So, if a supplier sets a high MOQ, orders will be larger, and inventory fluctuations will be more marked. Suppliers set MOQs to avoid wasting time and resources on orders that deliver little or no profit. The impact of MOQs when managing your inventory, Tips to help navigate the complexities of MOQs, Netstock recognized as leader in G2 Summer 2022 Grid Reports, Five tips to manage supplier risk in your supply chain, Carrying excess stock? What is the impact of minimum order quantity on inventory? Dont be tempted to take shortcuts and ask for cheaper materials in the manufacturing process. The wholesale business is competitive, and one should always look for easier alternatives. PRO TIP: Always try to negotiate supplier pricing before you start the relationship (even if its $1 or a few cents less than the listed price). Imagine that this bolt manufacturer receives three orders a day, each with an average of 7,500 units. Consider calculating your MOQ to your customers as a safeguard. MOQs are an efficient way to save costs and deliver products. From the buyers point of view, MOQs clearly constitute a constraint. Having this in place weeds out customers who want to buy lower quantities, which leads to unprofitable orders. Stock Keeping Units (SKUs), if not managed properly, can severely affect the handling costs. Your friend may cut you a better deal. Even maintaining an inventory requires the costs of their own. This results in improved product quality, which also benefits the customer. The structuring of MOQs can sometimes be complicated, as it can require split payments or recurring payments. , if not managed properly, can severely affect the handling costs. Avoid the chaos of unpredictable consumer demand, Netstock launches app to enable predictive inventory optimization for the modern supply chain.

If the item in question is made regularly, you may negotiate a lower MOQ. When you order the MOQ, you pay 50%, receive half the shipment, and take the balance of the stock a few months later.

As noted, this will usually be a minimum value or quantity of units. If your customers have been ordering 50 units of an item, consider making that your MOQ. Of course, the desired MOQ for the supplier and the business may be different, so it is important to choose the right partner. Warehouse WiFi: another pillar of logistics, Value-stream mapping (VSM): how to identify inefficiencies in the warehouse, Fast-moving consumer goods: all about FMCG logistics, Cycle service level: variable supply chain to prioritize customer satisfaction, Procurement in logistics: the key to efficient service, Benefits of gamification tools in logistics. Suppliers will collect extensive data to determine the point at which an MOQ makes the most money. If the MOQ is low, on the other hand, these stock variations will be less accentuated. Usually, a manufacturer will set higher MOQs because they require more resources to create the product than an MOQ defined by a supplier providing to a wholesaler or retailer. A Checklist for Choosing the Best POS for Your Business, 5 Tips for Training Your Employees on a New POS, The 7 Best Shopify Apps for Engaging Retail Customers, The Future of Retail Report [Free Download], Product Pricing: 5 Steps to Set Prices For Wholesale and Retail, Retail Jobs: 8 Common Retail Positions, Their Duties, and Who to Hire First, Whats a SKU Number? But when that becomes impossible, its time to look at other options. It is equally important to get paid for your MOQ. Machinery, materials, shipment costs, bookkeeping costs, and billing costs are just a few examples.

As noted, this will usually be a minimum value or quantity of units. If your customers have been ordering 50 units of an item, consider making that your MOQ. Of course, the desired MOQ for the supplier and the business may be different, so it is important to choose the right partner. Warehouse WiFi: another pillar of logistics, Value-stream mapping (VSM): how to identify inefficiencies in the warehouse, Fast-moving consumer goods: all about FMCG logistics, Cycle service level: variable supply chain to prioritize customer satisfaction, Procurement in logistics: the key to efficient service, Benefits of gamification tools in logistics. Suppliers will collect extensive data to determine the point at which an MOQ makes the most money. If the MOQ is low, on the other hand, these stock variations will be less accentuated. Usually, a manufacturer will set higher MOQs because they require more resources to create the product than an MOQ defined by a supplier providing to a wholesaler or retailer. A Checklist for Choosing the Best POS for Your Business, 5 Tips for Training Your Employees on a New POS, The 7 Best Shopify Apps for Engaging Retail Customers, The Future of Retail Report [Free Download], Product Pricing: 5 Steps to Set Prices For Wholesale and Retail, Retail Jobs: 8 Common Retail Positions, Their Duties, and Who to Hire First, Whats a SKU Number? But when that becomes impossible, its time to look at other options. It is equally important to get paid for your MOQ. Machinery, materials, shipment costs, bookkeeping costs, and billing costs are just a few examples. Especially when it comes to e-commerce, where. Having capital tied up in excess stock places businesses at Read More. Thats why. Finally, if a supplier just wont budge on its MOQ, you can always offer to pay more per unit. Contact us so we can help you find the most adequate solution. Set reorder points in Shopify Admin to get low stock notifications and ensure you have enough lead time to replenish inventory of a product before quantities reach zero. Build accurate forecasts with predictive intelligence. Generate and place optimized orders with a few clicks. An inventory turn is how businesses profit from their inventory by measuring how many times they have sold and replaced stock over a given period.

Through order confirmations, online store owners can send confirmations or address correction messages for the orders that are deemed risky or have incomplete information in them. Align data & decision-making across your organization. How to use and Create a New UPI ID, Difference between Payment Gateway and Payment Processor, ESI Calculation How to Calculate ESI (With Example), How to Get a Patent in India: Everything You Need to Know, GST Registration for Freelancers: A Complete Guide, The Definitive Income Tax Guide for Freelancers. Figuring out MOQ is not science. Shopify automatically syncs stock quantities as you receive, sell, return, or exchange products online or in storeno manual reconciling necessary. companies and suppliers continue to deal with an unprecedented number of hurdles to meet increasing demand. Last week, the [US] government reported that the economy grew at its slowest pace in more than a year in the third quarter because of widespread shortages tied to the COVID-19 pandemic. If a supplier buys a product for Rs. Start making better inventory decisions today. The other challenging thing while forming a strategy on MOQ is the use of the data available. Once suppliers determine demand, calculate holding costs, and find a break-even point, they set their MOQs for each product type. This is when your product sales (or your suppliers sales) are equal to business expenses. In other words, what profitability you want to obtain with each minimum order quantity, who your target customer is, and how you want to compete with other suppliers. Augmented Reality in Retail: How Retailers are Using AR for Better Shopping Experiences, Do Retailers Need a Digital Fashion Strategy? The minimum order quantity or MOQ refers to the very least number of units of a product that a supplier is willing to sell. MOQs in almost all cases is above the point at which the suppliers hit break even. This helps their inventory management and your bottom line. Production cost per unit is another factor directly related to minimum order quantity.

A Simple Guide to Understanding Minimum Order Quantities (MOQs) in Retail. We hate SPAM and promise to keep your email address safe.

An MOQ is the smallest number of items one can order in one delivery from a supplier.

An MOQ is the smallest number of items one can order in one delivery from a supplier. Learn the fundamentals to optimize your inventory. Be careful not to sacrifice quality. Customers ranked Netstock as a Leader for the seventh consecutive reporting season. Heres an example: You buy pens at $.20 each. Suppliers review historical data to forecast demand and use it to define the inventory quantities needed to satisfy market fluctuations.