What Can We Expect from Hologram Technology in the Future? All products featured on the PAC blog are available through the www.gotopac.com webstore. BS 5295 Class 1 also requires that the greatest particle present in any sample can not exceed 5 m.

Office Hours: 8am - 5pm CST, Production Automation Corporation (PAC) is a distributors of supplies, equipment, and controlled environments for life science, aerospace, electronics, and industrial manufacturing industries. The opposite is done e.g. Turbulent, or non unidirectional, air flow uses both laminar air flow hoods and nonspecific velocity filters to keep air in a cleanroom in constant motion, although not all in the same direction.  {\displaystyle {\text{N}}} Pressure levels are set so that the cleanest air flows into spaces with less-clean air. 2.08 Common materials such as paper, pencils, and fabrics made from natural fibers are often excluded, because they shed particulates in use. How to Certify a Cleanroom with Kanomax Hand Held Particle Counters. Within, air is constantly recirculated through fan units containing high-efficiency particulate absorbing filters (HEPA), and/or ultra-low particulate air (ULPA) filters to remove internally generated contaminants. Cleanrooms are classified according to the number and size of particles permitted per volume of air. f In order to specify this particle size in association with ISO Class 5, the macroparticle descriptor M may be adapted and used in conjunction with at least one other particle size. They vary in size and complexity, and are used extensively in industries such as semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy. in the case of high level bio-laboratories, handling contaminous viruses; those are always held at negative pressure, with the exhaust being passed through high efficiency filters, and further sterilizing procedures. Because 1m3 is about 35ft3, the two standards are mostly equivalent when measuring 0.5m particles, although the testing standards differ. A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. This refers to the number of times each hour that filtered outside air replaces the existing volume in a building or chamber. The idea is to ensure that filtered air always flows from cleanest to less-clean spaces. e Sample collection limitations for both particles in low concentrations and sizes greater than 1 m make classification at this particle size inappropriate, due to potential particle losses in the sampling system. Both are still cleanrooms, because the particulate level inside is maintained within very low limits. [2][3], The majority of the integrated circuit manufacturing facilities in Silicon Valley were made by three companies: MicroAire, PureAire, and Key Plastics. The rough air seeks to trap particles that may be in the air and drive them towards the floor, where they enter filters and leave the cleanroom environment. The advantage of laminar over turbulent airflow is that it provides a uniform environment and prevents air pockets where contaminants might congregate. Cleaning chemicals used tend to involve sticky elements to trap dust, and may need a second step with light molecular weight solvents to clear. Institute of Environmental Sciences & Technology (IEST) 5005 Newport Drive, Suite 506 Rolling Meadows, IL 60008-3841 http://www.iest.org Phone: (847) 255-1561 Fax: (847) 255-1699. [5] They have been argued to lower costs of scaling the technology, and to be less susceptible to catastrophic failure. Between the large and the small, there are also modular cleanrooms. Cleanrooms are used in practically every industry where small particles can adversely affect the manufacturing process.

{\displaystyle {\text{N}}} Pressure levels are set so that the cleanest air flows into spaces with less-clean air. 2.08 Common materials such as paper, pencils, and fabrics made from natural fibers are often excluded, because they shed particulates in use. How to Certify a Cleanroom with Kanomax Hand Held Particle Counters. Within, air is constantly recirculated through fan units containing high-efficiency particulate absorbing filters (HEPA), and/or ultra-low particulate air (ULPA) filters to remove internally generated contaminants. Cleanrooms are classified according to the number and size of particles permitted per volume of air. f In order to specify this particle size in association with ISO Class 5, the macroparticle descriptor M may be adapted and used in conjunction with at least one other particle size. They vary in size and complexity, and are used extensively in industries such as semiconductor manufacturing, pharmaceuticals, biotech, medical device and life sciences, as well as critical process manufacturing common in aerospace, optics, military and Department of Energy. in the case of high level bio-laboratories, handling contaminous viruses; those are always held at negative pressure, with the exhaust being passed through high efficiency filters, and further sterilizing procedures. Because 1m3 is about 35ft3, the two standards are mostly equivalent when measuring 0.5m particles, although the testing standards differ. A cleanroom or clean room is an engineered space, which maintains a very low concentration of airborne particulates. This refers to the number of times each hour that filtered outside air replaces the existing volume in a building or chamber. The idea is to ensure that filtered air always flows from cleanest to less-clean spaces. e Sample collection limitations for both particles in low concentrations and sizes greater than 1 m make classification at this particle size inappropriate, due to potential particle losses in the sampling system. Both are still cleanrooms, because the particulate level inside is maintained within very low limits. [2][3], The majority of the integrated circuit manufacturing facilities in Silicon Valley were made by three companies: MicroAire, PureAire, and Key Plastics. The rough air seeks to trap particles that may be in the air and drive them towards the floor, where they enter filters and leave the cleanroom environment. The advantage of laminar over turbulent airflow is that it provides a uniform environment and prevents air pockets where contaminants might congregate. Cleaning chemicals used tend to involve sticky elements to trap dust, and may need a second step with light molecular weight solvents to clear. Institute of Environmental Sciences & Technology (IEST) 5005 Newport Drive, Suite 506 Rolling Meadows, IL 60008-3841 http://www.iest.org Phone: (847) 255-1561 Fax: (847) 255-1699. [5] They have been argued to lower costs of scaling the technology, and to be less susceptible to catastrophic failure. Between the large and the small, there are also modular cleanrooms. Cleanrooms are used in practically every industry where small particles can adversely affect the manufacturing process.

The appendix contained no ACR standards for pharmaceutical, healthcare or biotech applications, which may require higher ACR regulations. By working directly with manufacturers, Mel deciphers technical documentation and outlines product use in real-world environments. You'll find. For Class 10 cleanrooms, careful gown wearing procedures with a zipped cover all, boots, gloves and complete respirator enclosure are required.

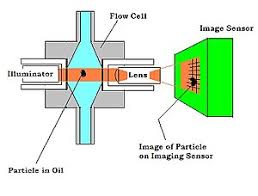

Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1m or larger permitted per m3 of air. ISO 14644-2 describes the type and frequency of testing required to conform to certain standards. A critical factor in cleanroom design is controlling air-change per hour (ACH), also known as the air-change rate, or ACR. The "cleanest" cleanroom is a class 1 and the "dirtiest" a class 9. Laminar, or unidirectional, air flow systems direct filtered air downward or in horizontal direction in a constant stream towards filters located on walls near the cleanroom floor or through raised perforated floor panels to be recirculated. This standard is about to be superseded by BS EN ISO 14644-1. An anteroom (known as a "gray room") is used to put on clean-room clothing. The study also found that the "[b]est practice for ACRs is to design new facilities at the lower end of the recommended ACR range," with variable speed drives (VSDs) built in so that air flow adjustments can be made under actual operating conditions. The use of ceiling mounted air returns is contradictory to proper cleanroom system design. Federal Standard 209E is used domestically. in many nuclear power plants, which operate as low-grade inverse pressure cleanrooms, as a whole. Optical particle counters have several different ways to detect and measure particles. Cleanrooms typically come with a cleanliness level quantified by the number of particles per cubic meter at a predetermined molecule measure. For example, the rooms utilized in semiconductor manufacturing need not be sterile (i.e., free of uncontrolled microbes);[6], while the ones used in biotechnology usually must be. ISO class 3 is approximately equal to FS209E class 1, while ISO class 8 approximately equals FS209E class 100,000. Static discharge is of particular concern in the electronics industry, where it can instantly destroy components and circuitry. The other way around, a cleanroom can also help keep materials escaping from it. Laminar air flow systems are typically employed across 80% of a cleanroom ceiling to maintain constant air processing.

This standard is about to be superseded by BS EN ISO 14644-1. Cleanrooms are classified according to the number and size of particles permitted per volume of air. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m3. 3 Achieving the optimal air change rate requires proper ceiling fan coverage. Cleanrooms can range from the very small to the very large. [10] Plenums between air handlers and fan filter units along with sticky mats may also be used. D This metric nomenclature is also accepted in the most recent 209E version of the Standard. What then is common to all cleanrooms is strict control of airborne particulates, possibly with secondary decontamination of air, surfaces, workers entering the room, implements, chemicals, and machinery. Some cleanrooms are kept at a positive pressure so if any leaks occur, air leaks out of the chamber instead of unfiltered air coming in. Drug Quality and Security Act (DQSA) created in Nov. 2013 in response to drug compounding deaths and serious adverse events. ISO Standard Clean Room Information | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap. In hospitals, theatres are similar to cleanrooms for surgical patients' operations with incisions to prevent any infections for the patient. Cleanrooms are classified according to the number and size of particles permitted per volume of air. So if we chose a small hand-held particle counter that had a flow rate of 2 liters per meter that would take about 120 minutes or 2 hours to sample the air. Proper cleanroom design encompasses the entire air distribution system, including provisions for adequate, downstream air returns. In Federal Standard 209 (A to D) of the USA, the number of particles equal to and greater than 0.5mm is measured in one cubic foot of air, and this count is used to classify the cleanroom. These competitors made laminar flow units, glove boxes, clean rooms and air showers, along with the chemical tanks and benches used in the 'Wet Process' building of integrated circuits. 503A addresses compounding by state or federally licensed facility by licensed personnel (pharmacist/ physicians), 503B pertaining to outsourcing facilities need direct supervision from a licensed pharmacist and do not need to be a licensed pharmacy. ISO 14644-1 defines the maximum concentration of particles per class and per particle size with the following formula[21], C Cleanrooms maintain particulate-free air through the use of either HEPA or ULPA filters employing laminar or turbulent air flow principles. In vertical flow rooms, this means the use of low wall air returns around the perimeter of the zone. This calculates the number of liters of air that need to be sampled in your cleanroom. Designers and operators need evidence from others who have tried similar strategies in order to address the perceived risks of lowering air change rates.". Log data and generate environmental reports real-time on screen, via printer or USB key, or export to Particles Plus Instrument Management Software. Many are in the final voting stage and can be legally used in the trade (see chart). Cleanroom garments include boots, shoes, aprons, beard covers, bouffant caps, coveralls, face masks, frocks/lab coats, gowns, glove and finger cots, hairnets, hoods, sleeves and shoe covers. The standard also allows interpolation, so it is possible to describe e.g. By minimizing turbulence, lower airflow may improve cleanliness. N Depending on the room classification or function, personnel gowning may be as limited as lab coats and hairnets, or as extensive as fully enveloped in multiple layered bunny suits with self contained breathing apparatus. Meeting Class 100 standards using the low-end air change recommendation (240/hour) inside a 12 x 12 x 7 (3302 mm x 3302 mm x 2134 mm) cleanroom, with 1008 cu.

Vice versa, the ones utilized for biotechnology need not be absolutely pure of nanoscale inorganic salts, such as rust, while nanotechnology absolutely requires it. The ambient air outside in a typical city environment contains 35,000,000 particles per cubic meter, 0.5 micron and larger in diameter, corresponding to an ISO 9 cleanroom which is at the lowest level of cleanroom standards. For ISO 14644 compliance, all particle counting equipment requires a calibration certificate. Email: [emailprotected] This metric nomenclature is also accepted in the most recent 209E version of the Standard. The air then leaves thru exhaust grills to outside the cleanroom. The light blocking method can detect particles larger than a micrometer in size and is based on the amount of light the particle blocks when passing through the light source. Determining the appropriate number of air changes for a particular application requires careful evaluation of factors such as the number of personnel, effectiveness of garbing protocol, frequency of access, and cleanliness of process equipment. Rumsey issued a caveat, then brushed it aside by citing research subsequent to Berkeleys: "Air cleanliness is a critical component of any cleanroom, far outweighing energy saving priorities.  However, for safety reasons, shoe soles must not create slipping hazards. Personnel selected to work in cleanrooms undergo extensive training in contamination control theory. Types of Cleanrooms by Clean Air Technology and Expertise: ISO 8 Cleanroom, ISO 5 Cleanroom, ISO 7 Cleanroom, Specifying Cleanroom Requirements and Guidelines, Cleanroom Designers, Cleanroom Contractors, Cleanroom Manufacturers, ISO Class 100 Cleanrooms, Class 10000 Cleanrooms, Class 100000 Cleanrooms, Hardwall Cleanrooms, Softwall Cleanrooms, ISO Class 1 Cleanrooms, ISO Class 2 Cleanrooms, ISO Class 3 Cleanroom, ISO Class 4 Cleanrooms, ISO Class 5 Cleanrooms, ISO Class 6 Cleanroom, ISO Class 7 Cleanrooms, ISO Class 8 Cleanrooms, ISO Class 9 Cleanrooms, Cleanrooms Grade A, B, C, D, FDA Cleanrooms, Certified Cleanrooms, USP 797 Cleanrooms Pharmaceutical, USP 800 Cleanroom Hazardous Drugs, HazCom, Clean Room Designations, Cleanroom Installation. The air then is pulled by HEPA fan filter units back into the cleanroom. The advantage of this approach is the lower cost. Corners like the wall to wall, wall to floor, wall to ceiling are avoided by providing coved surface and all joints need to be sealed with epoxy sealant to avoid any deposition or generation of particles at the joints, by vibration and friction. On the one hand a single user laboratory can be built to cleanroom standards within several square meters, and on the other entire manufacturing facilities can be contained within a cleanroom with factory floors covering thousands of square meters. PAC no longer stocks or distributes Airy products as they are generally discontinued by the manufacturer. For the method used to avoid copyright infringement, see, Dust-free room for research or production, Air flow pattern for "Turbulent Cleanroom", Cleanroom classification and standardization, William (Bill) C. McElroy Jr., MicroAire Engineering Manager and acting VP; Kay Plastics Engineering Manager; PureAire Drafting Room Manager, International Organization for Standardization, "Willis Whitfield, Clean Room Inventor, Dies at 92", "Sandia physicist, cleanroom inventor dies at 92", "Willis Whitfield - Father of the Cleanroom", In NASAs Sterile Areas, Plenty of Robust Bacteria, "Kenall Cleanroom and Containment Lighting", "Effectiveness of a shielded ultraviolet C air disinfection system in an inpatient pharmacy of a tertiary care children's hospital", "UV helps maintain cleanroom air quality", "Chemical compatibility of fused filament fabrication-based 3-D printed components with solutions commonly used in semiconductor wet processing", "Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing", "Cleanroom and Controlled Environment Attire - ANSI Blog", "Space Station Processing Facility (SSPF)", "Cleanroom Classification / Particle Count / FS209E / ISO TC209 /", "ISO 14644-1:2015 - Cleanrooms and associated controlled environments -- Part 1: Classification of air cleanliness by particle concentration", "FD&C Act Provisions that Apply to Human Drug Compounding", "Understanding Cleanroom Classifications", "BS 5295-0:1989 - Environmental cleanliness in enclosed spaces. For instance, some manufacturers insist on as many as 720 air changes per hour to meet Class 10 standards. Combining all three factors ACR, ceiling coverage and airflow velocity-results in the following table: Before deciding on the appropriate velocity and air changes for your application, Terra Universal recommends careful evaluation of factors such as number of personnel, effectiveness of garbing protocol, access frequency and cleanliness of process equipment. [11] UV devices can be fitted into ceiling light fixtures and irradiate air, killing potentially infectious particulates, including 99.99 percent of airborne microbial and fungal contaminants. So we would need to sample 240.96 liters of air. This near-100% coverage provides a laminar flow of filtered air to quickly remove contaminants from the room, thus meeting FS209E standards for Class 10 and ISO Class 1 standards. So, for example, an ISO class 5 cleanroom has at most 105 particles/m3. Cleanroom clothing is used to prevent substances from being released off the wearer's body and contaminating the environment. How Do Particle Counters Work? Buffed stainless steel or powder-coated mild steel sandwich partition panels and ceiling panel are used, instead of iron alloys prone to rusting and then flaking. And there is some controversy.

However, for safety reasons, shoe soles must not create slipping hazards. Personnel selected to work in cleanrooms undergo extensive training in contamination control theory. Types of Cleanrooms by Clean Air Technology and Expertise: ISO 8 Cleanroom, ISO 5 Cleanroom, ISO 7 Cleanroom, Specifying Cleanroom Requirements and Guidelines, Cleanroom Designers, Cleanroom Contractors, Cleanroom Manufacturers, ISO Class 100 Cleanrooms, Class 10000 Cleanrooms, Class 100000 Cleanrooms, Hardwall Cleanrooms, Softwall Cleanrooms, ISO Class 1 Cleanrooms, ISO Class 2 Cleanrooms, ISO Class 3 Cleanroom, ISO Class 4 Cleanrooms, ISO Class 5 Cleanrooms, ISO Class 6 Cleanroom, ISO Class 7 Cleanrooms, ISO Class 8 Cleanrooms, ISO Class 9 Cleanrooms, Cleanrooms Grade A, B, C, D, FDA Cleanrooms, Certified Cleanrooms, USP 797 Cleanrooms Pharmaceutical, USP 800 Cleanroom Hazardous Drugs, HazCom, Clean Room Designations, Cleanroom Installation. The air then is pulled by HEPA fan filter units back into the cleanroom. The advantage of this approach is the lower cost. Corners like the wall to wall, wall to floor, wall to ceiling are avoided by providing coved surface and all joints need to be sealed with epoxy sealant to avoid any deposition or generation of particles at the joints, by vibration and friction. On the one hand a single user laboratory can be built to cleanroom standards within several square meters, and on the other entire manufacturing facilities can be contained within a cleanroom with factory floors covering thousands of square meters. PAC no longer stocks or distributes Airy products as they are generally discontinued by the manufacturer. For the method used to avoid copyright infringement, see, Dust-free room for research or production, Air flow pattern for "Turbulent Cleanroom", Cleanroom classification and standardization, William (Bill) C. McElroy Jr., MicroAire Engineering Manager and acting VP; Kay Plastics Engineering Manager; PureAire Drafting Room Manager, International Organization for Standardization, "Willis Whitfield, Clean Room Inventor, Dies at 92", "Sandia physicist, cleanroom inventor dies at 92", "Willis Whitfield - Father of the Cleanroom", In NASAs Sterile Areas, Plenty of Robust Bacteria, "Kenall Cleanroom and Containment Lighting", "Effectiveness of a shielded ultraviolet C air disinfection system in an inpatient pharmacy of a tertiary care children's hospital", "UV helps maintain cleanroom air quality", "Chemical compatibility of fused filament fabrication-based 3-D printed components with solutions commonly used in semiconductor wet processing", "Compatibility of 3-D printed devices in cleanroom environments for semiconductor processing", "Cleanroom and Controlled Environment Attire - ANSI Blog", "Space Station Processing Facility (SSPF)", "Cleanroom Classification / Particle Count / FS209E / ISO TC209 /", "ISO 14644-1:2015 - Cleanrooms and associated controlled environments -- Part 1: Classification of air cleanliness by particle concentration", "FD&C Act Provisions that Apply to Human Drug Compounding", "Understanding Cleanroom Classifications", "BS 5295-0:1989 - Environmental cleanliness in enclosed spaces. For instance, some manufacturers insist on as many as 720 air changes per hour to meet Class 10 standards. Combining all three factors ACR, ceiling coverage and airflow velocity-results in the following table: Before deciding on the appropriate velocity and air changes for your application, Terra Universal recommends careful evaluation of factors such as number of personnel, effectiveness of garbing protocol, access frequency and cleanliness of process equipment. [11] UV devices can be fitted into ceiling light fixtures and irradiate air, killing potentially infectious particulates, including 99.99 percent of airborne microbial and fungal contaminants. So we would need to sample 240.96 liters of air. This near-100% coverage provides a laminar flow of filtered air to quickly remove contaminants from the room, thus meeting FS209E standards for Class 10 and ISO Class 1 standards. So, for example, an ISO class 5 cleanroom has at most 105 particles/m3. Cleanroom clothing is used to prevent substances from being released off the wearer's body and contaminating the environment. How Do Particle Counters Work? Buffed stainless steel or powder-coated mild steel sandwich partition panels and ceiling panel are used, instead of iron alloys prone to rusting and then flaking. And there is some controversy.  William (Bill) C. McElroy Jr. worked as engineering manager, drafting room supervisor, QA/QC, and designer for all three companies and his designs added 45 original patents to the technology of the time. How to Certify or Test a Cleanroom with a Handheld Particle Counter, New: Particles Plus Cleanroom Particle Counters and Air Quality Monitors. ACR is a prime variable in determining ISO and Federal cleanliness standards. Why Do Corona Ionizers Need Regular Maintenance.

William (Bill) C. McElroy Jr. worked as engineering manager, drafting room supervisor, QA/QC, and designer for all three companies and his designs added 45 original patents to the technology of the time. How to Certify or Test a Cleanroom with a Handheld Particle Counter, New: Particles Plus Cleanroom Particle Counters and Air Quality Monitors. ACR is a prime variable in determining ISO and Federal cleanliness standards. Why Do Corona Ionizers Need Regular Maintenance.

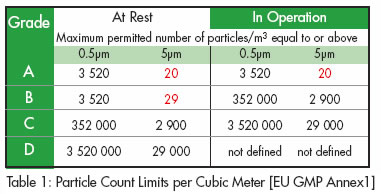

Condensation particle counters can detect particles as small as 2nm, which cannot be detected with optical particle counters. Plug it into the formula for Vs=(20/83) x 1000, and Vs=240.96. The type of cleanroom garments used should reflect the cleanroom and product specifications. To be exact, a cleanroom has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. The cleanroom classification standards FS 209E and ISO 14644-1 require specific particle count measurements and calculations to classify the cleanliness level of a cleanroom or clean area. In Federal Standard 209 (A to D) of the USA, the number of particles equal to and greater than 0.5m is measured in one cubic foot of air, and this count is used to classify the cleanroom. By comparison an ISO 14644-1 level 1 certified cleanroom permits no particles in that size range, and just 12 particles for each cubic meter of 0.3 m and smaller. Laminar airflow means that filtered air is uniformly supplied in one direction (at a fixed velocity) in parallel streams, usually vertically. EU GMP guidelines are more stringent than others, requiring cleanrooms to meet particle counts at operation (during manufacturing process) and at rest (when manufacturing process is not carried out, but room AHU is on). The selection of material for the construction of a cleanroom should not generate any particulates, hence monolithic epoxy or polyurethane floor coating is preferred. General introduction, terms and definitions for clean rooms and clean air devices", Cleanroom Wiki--The Global Society For Contamination Control (GSFCC), The Secretariat to ISO/TC 209 Cleanrooms and associated controlled environments, the group of experts who negotiate all aspects of the 14644 standard, https://en.wikipedia.org/w/index.php?title=Cleanroom&oldid=1098334799, Short description is different from Wikidata, Creative Commons Attribution-ShareAlike License 3.0. Modular vs. 4-Legged Workstations: Which Design is Best for Your Organization? c Concentration limits are not applicable in this region of the table due to very high particle concentration. [1] As employee of the Sandia National Laboratories, Whitfield created the initial plans for the cleanroom in 1960.

First, outside air entering a cleanroom is filtered and cooled by several outdoor air handlers using progressively finer filters to exclude dust. [27] BS 5295 has been superseded, withdrawn since the year 2007 and replaced with "BS EN ISO 14644-6:2007". The second factor is the flow rate capacity of the particle counter. Common bacterial genera include Micrococcus, Staphylococcus, Corynebacterium, and Bacillus, and fungal genera include Aspergillus and Penicillium.[14]. The air is constantly recirculating and byu continuously passing thru HEPA filtration removing particles from the air each time. When cleaning, only special mops and buckets are used. FS209E contains six classes, while the ISO 14644-1 classification system adds two cleaner standards and one dirtier standard (see chart below). This practice is common e.g. Thus, even by international law, any probes we send to outer space must be sterile, and so to be handled in cleanroom conditions.

Large numbers like "class 100" or "class 1000" refer to FED_STD-209E, and denote the number of particles of size 0.5 m or larger permitted per cubic foot of air. Vs is the minimum single sample volume per location. b These concentrations will lead to large air sample volumes for classification. Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. Potential advantages of UV-based decontamination includes a reduced reliance on chemical disinfectants and the extension of HVAC filter life. ISO delineates three cleanroom classification standards: as-built, at-rest and operational. Before global cleanroom classifications and standards were adopted by the International Standards Organization (ISO), the U.S. General Service Administrations standards (known as FS209E) were applied virtually worldwide. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m.

They are light blocking, light scattering, and direct imaging. For that reason, there is no such thing as zero particle concentration. Particle levels are usually tested using a particle counter and microorganisms detected and counted through environmental monitoring methods. A discrete, light-scattering airborne particle counter is used to determine the concentration of airborne particles, equal to and larger than the specified sizes, at designated sampling locations. Laminar, or unidirectional, air flow systems direct filtered air downward in a constant stream. ft. of volume, requires 6 FFUs.  These three companies were the pioneers of the use of Teflon for airguns, chemical pumps, scrubbers, water guns, and other devices needed for the production of integrated circuits. Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 m or larger permitted per cubic meter of air. Larger portable units have a fixed location and continuously monitor the air 24/7. The key component is the High Efficiency Particulate Air (HEPA) filter that is used to trap particles that are 0.3 micron and larger in size. Rumsey then went on to cite studies done by International Sematech (Austin, Texas); the Massachusetts Institute of Technology (Cambridge, Mass. Once the required air change figure is established, the number of required FFUs can be determined using this formula: No. Such coverage, especially in a large cleanroom, can lead to higher energy consumption, thus increasing costs for both initial construction and ongoing operation. {\displaystyle {\text{C}}_{\text{N}}=10^{\text{N}}\left({\frac {0.1}{\text{D}}}\right)^{2.08}}. Some classes do not require testing some particle sizes, because the concentration is too low or too high to be practical to test for, but such blanks should not be read as zero. Shop Online: www.gotopac.com {\displaystyle {\text{D}}} In the UK, British Standard 5295 is used to classify cleanrooms. The PG&E/Berkeley study caused many designers to reduce fan sizes. The standard also allows interpolation, so it is possible to describe e.g. How Often Does a Particle Counter Require Recalibration? Sometimes particulates exiting the compartment are also of concern, such as in research into dangerous viruses, or where radioactive materials are being handled. Some cleanroom HVAC systems control the humidity to such low levels that extra equipment like air ionizers are required to prevent electrostatic discharge problems. ISO cleanroom classifications are rated according to how much particulate of specific sizes exist per cubic meter (see second chart). [12] UV light has previously been used to clean surface contaminants in sterile environments such as hospital operating rooms. On the other hand, active ions in the air can harm exposed components as well. In a normal home, an air-conditioner changes room air 0.5 to 2 times per hour. A 30-percent reduction in air change rate results in a power reduction of approximately 66 percent. Thus, multiple pressure levels may need to be maintained. Non-operational cleanrooms are found in the lower range; operational cleanrooms higher.

These three companies were the pioneers of the use of Teflon for airguns, chemical pumps, scrubbers, water guns, and other devices needed for the production of integrated circuits. Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 m or larger permitted per cubic meter of air. Larger portable units have a fixed location and continuously monitor the air 24/7. The key component is the High Efficiency Particulate Air (HEPA) filter that is used to trap particles that are 0.3 micron and larger in size. Rumsey then went on to cite studies done by International Sematech (Austin, Texas); the Massachusetts Institute of Technology (Cambridge, Mass. Once the required air change figure is established, the number of required FFUs can be determined using this formula: No. Such coverage, especially in a large cleanroom, can lead to higher energy consumption, thus increasing costs for both initial construction and ongoing operation. {\displaystyle {\text{C}}_{\text{N}}=10^{\text{N}}\left({\frac {0.1}{\text{D}}}\right)^{2.08}}. Some classes do not require testing some particle sizes, because the concentration is too low or too high to be practical to test for, but such blanks should not be read as zero. Shop Online: www.gotopac.com {\displaystyle {\text{D}}} In the UK, British Standard 5295 is used to classify cleanrooms. The PG&E/Berkeley study caused many designers to reduce fan sizes. The standard also allows interpolation, so it is possible to describe e.g. How Often Does a Particle Counter Require Recalibration? Sometimes particulates exiting the compartment are also of concern, such as in research into dangerous viruses, or where radioactive materials are being handled. Some cleanroom HVAC systems control the humidity to such low levels that extra equipment like air ionizers are required to prevent electrostatic discharge problems. ISO cleanroom classifications are rated according to how much particulate of specific sizes exist per cubic meter (see second chart). [12] UV light has previously been used to clean surface contaminants in sterile environments such as hospital operating rooms. On the other hand, active ions in the air can harm exposed components as well. In a normal home, an air-conditioner changes room air 0.5 to 2 times per hour. A 30-percent reduction in air change rate results in a power reduction of approximately 66 percent. Thus, multiple pressure levels may need to be maintained. Non-operational cleanrooms are found in the lower range; operational cleanrooms higher.